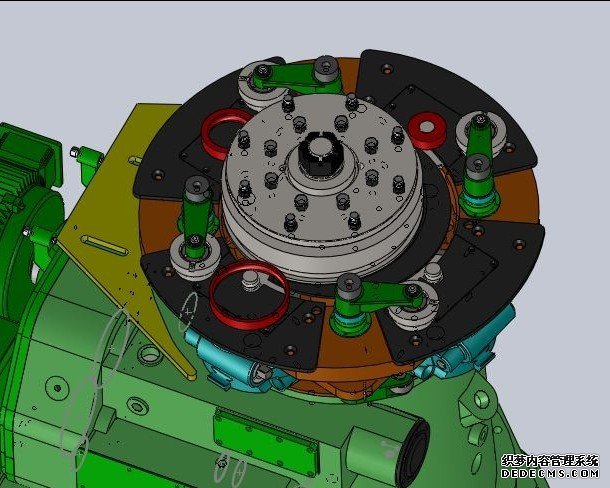

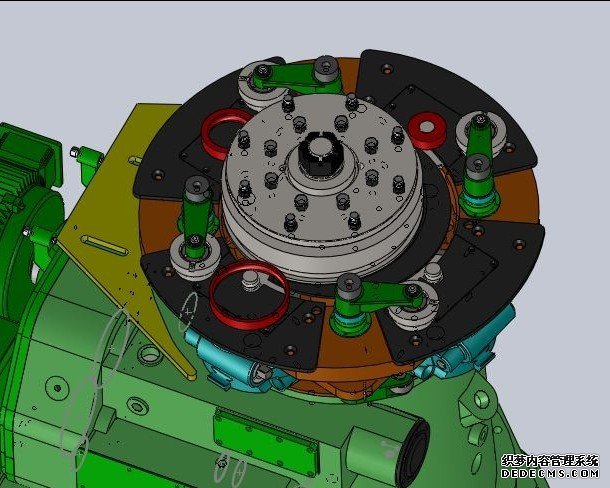

rings rolling machine-four working station

(人气:)

来源:

作者:admin

发布时间:2018-08-24 16:34

字号: T|T

rings rolling machine-four working station

Quanyue CNC Co., Ltd.- providing forging equipment, forging supplies, machinery, ring parts, implements, production lines, sales, manufacturers, SMS, bearings, flanges, slewing rings, ring rolling machines, seamless ring parts, ring rolling mills, hydraulic presses , cylinder, hydraulic valve, hydraulic system, hydraulic control, CNC, coil, shear, coil cutting, palletizing, automatic stacking, extrusion, forging, auto parts, automotive interiors, molds, renovation, overhaul, etc. service. Welcome communication.

KFRW t400 Multi-spindle rings rolling machine

GENERAL TECHNICAL CHARACTERESTICS:

l Purpose – bearing rings blanks hot rolling.

l Blanks material – bearing steels ШХ15СГ、ШХ4 GOST 801-78 、GOST 801-78、GCr15、GCr15SiMn、GCr4、GCr15SiMo、GCr18MoG20CrMo、G20CrNiMo、G20CrNi2Mo、G20Cr2Ni4、G10CrNi3Mo、G20Cr2Mn2Mo。

l Metal temperature before rolling - 1000-1100 оС

l Location of rolls axes – vertical, number of inner rolls – not less than 4.

l Loading/unloading of parts – manual

l Rolling accuracy – variability of sizes (tolerance) under control diameter and end-faces – not more than 1,5 mm

l Main motion drive – electric.

l Power supply requirements - АС 380 В +/-10 %, three phases, 50 Hz.

Rings parameters after rolling

Quanyue CNC Co., Ltd.- providing forging equipment, forging supplies, machinery, ring parts, implements, production lines, sales, manufacturers, SMS, bearings, flanges, slewing rings, ring rolling machines, seamless ring parts, ring rolling mills, hydraulic presses , cylinder, hydraulic valve, hydraulic system, hydraulic control, CNC, coil, shear, coil cutting, palletizing, automatic stacking, extrusion, forging, auto parts, automotive interiors, molds, renovation, overhaul, etc. service. Welcome communication.

KFRW t400 Multi-spindle rings rolling machine

GENERAL TECHNICAL CHARACTERESTICS:

l Purpose – bearing rings blanks hot rolling.

l Blanks material – bearing steels ШХ15СГ、ШХ4 GOST 801-78 、GOST 801-78、GCr15、GCr15SiMn、GCr4、GCr15SiMo、GCr18MoG20CrMo、G20CrNiMo、G20CrNi2Mo、G20Cr2Ni4、G10CrNi3Mo、G20Cr2Mn2Mo。

l Metal temperature before rolling - 1000-1100 оС

l Location of rolls axes – vertical, number of inner rolls – not less than 4.

l Loading/unloading of parts – manual

l Rolling accuracy – variability of sizes (tolerance) under control diameter and end-faces – not more than 1,5 mm

l Main motion drive – electric.

l Power supply requirements - АС 380 В +/-10 %, three phases, 50 Hz.

Rings parameters after rolling

| Controlled parameters | Size tolerance, mm |

| Variation in wall thickness, not more | 1,2 |

| Ovality and conicity of outer surface | 1.5 |

| Ovality and conicity of inner surface | 2.5 |

| Forging width variation | 1.5 |

| Circular burr in axial direction width not more | 2.0 |

| Circular burr in radial direction width not more | 2.0 |

| Ends gradation and concavity from minimum size, not more | 0,8 |

| Underfill in angles with radius R not more | 6,0 |

| Surface defects of forging character, depth of marks on the outer surface fromminimum size, not more (GOST 8479-70) | 0.5 |

| Surface defects of forging character, depth of marks on the inner surface fromminimum size, not more (GOST 8479-70) | 0.5 |

| Surface defects of forging character, depth of marks on width from minimumsize, not more {GOST 8479-70) | 0.7 |

You might be interested

-

3000mm ring forging production

3000mm ring forging production line;Jinan Quanyue CNC. is a supplier of equipment in the field of ring parts .It provides forging hydraulic presses, ring rollin...... [more] -

ring rolling machine of 5000m

The development of Jinan Quanyue computer numerical control benefit from MaANSHAN LEE INDUSTRIAL CO. LTD, under the leadership of the trust and strongly support...... [more]

加入收藏

加入收藏 电邮

电邮 打印文章

打印文章 写信给编辑

写信给编辑